Easier, faster, safer!Making the invisible danger visible - gas and leakage detection

Maximum support

for leakage detection

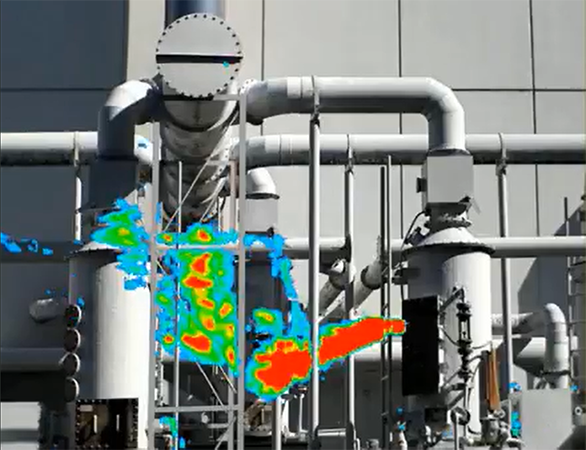

In the world of fluid mechanics, precise flow visualization is crucial for research, development and industrial applications. Air flows, temperature distributions and gas dispersions are invisible to the naked eye, but have a significant impact on the efficiency and safety of products and processes. With its highly developed FlowBOS systems, LaVision offers an innovative solution to make these invisible flows visible and measurable in real time – contactless, highly precise and without contaminating tracer materials.

With many years of experience in optical measurement technology, LaVision is a global leader in the development of high-precision solutions for industrial quality inspection. Our leak detection technologies set new standards in visual gas flow analysis and enable fast, reliable and contamination-free detection of gas and air leaks.

Why do world-leading companies rely on LaVision?

LaVision - Your partner for innovative leakage measurement technology

Customized measurement solutions for a wide range of industrial requirements

Highly sensitive systems for detecting the smallest leaks - from "micro-leaks" to large-scale leaks

Complete documentation & real-time analysis for direct integration into existing quality assurance systems

Proven technology for hydrogen, ammonia and alternative fuel applications

The FlowBOS principle: Detecting leaks without contact

LaVision’s FlowBOS technology uses optical flow analysis to make gas movements and leaks visible. Instead of using contaminating smoke tests or chemical indicators, FlowBOS relies on a highly sensitive optical process that clearly detects air turbulence and gas leaks.

Non-contact leakage detection: no impact on sensitive components or production environments

High sensitivity: even the finest micro-leaks in pipe systems, tanks or high-pressure valves can be detected

Real-time analysis: direct feedback and visualization of leaks for quick process adjustments

Flexible application: Suitable for a wide range of production and industrial areas

High scalability: Precise measurements both at close range for detailed leakage analyses and at long range for large-area tests

Flexible sensitivity: Adaptable to different environmental conditions to ensure optimum detection depending on the scenario

Applications - Where can FlowBOS detect leaks?

Indoor applications

(closed rooms & industrial environments)

- Quality control in production – leak testing of components, valves & tanks

- Acceptance tests for large and small appliances – Optimization of process reliability in production

- Inspection of installations & pipelines – Precise leakage detection without interrupting operations

- Safety testing of weld seams – detection of defects in metallic & non-metallic materials

- Leak testing in cleanrooms & pharmaceutical industry – Particle-free testing for sterile production conditions

- Testing gas pipes in industrial plants – minimizing explosion risks

Outdoor applications (open spaces, energy systems & infrastructure)

- Leakage tests for hydrogen, ammonia & alternative fuels – Maximum safety for new energy sources

- Inspection of hydrogen filling stations & LNG terminals – Ensuring the tightness of storage tanks

- Detection of gas leaks in pipelines – Non-contact leak detection along supply lines

- Safety tests for wind and solar systems – preventing leaks in hydrogen-based energy systems

- Comprehensive inspection of gas caverns & storage tanks – Real-time monitoring of large industrial plants

- Detection of environmental leaks – identification of uncontrolled gas emissions from landfills or chemical plants

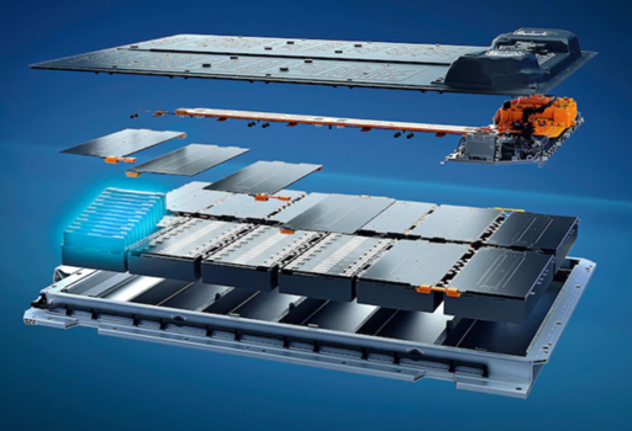

Battery testing with FlowBOS -

Maximum safety for e-mobility

The safety and efficiency of high-performance batteries are crucial to the success of electromobility. Especially in the development and production of lithium-ion batteries and future solid-state batteries, leak tests and gas leak analyses must meet the highest standards. Leaking battery housings, gas emissions or thermal anomalies can have a significant impact not only on performance but also on vehicle safety.

Other possible industrial applications

- Quality control in the production of components

- Acceptance of large and small appliances

- Inspection of installations

- Inspection of weld seams

- Clothing and protective equipment

- Laboratory systems

- Piping systems

Advantages of visualization with FlowBOS

Alternative fuels are used in various sectors in which precise measurement technology plays a key role:

Maximum safety – Quick identification of leaks reduces risks to people & the environment

Leakage detection for invisible gases: Hydrogen & Ammonia

Challenge: Hydrogen (H₂) and ammonia (NH₃) are colorless, often odorless gases with a high hazard potential. While hydrogen is extremely flammable, ammonia poses a particular challenge for safe handling due to its toxicity.

LaVision’s FlowBOS technology makes H₂ and NH₃ leaks visible for the first time – without complex sensors or chemical indicators.

Why FlowBOS is superior for leaks of invisible gases

While many systems rely on noise, heat radiation or particle emissions, FlowBOS visualizes the actual gas dispersion optically and in real time – contact-free and without contamination. Conventional technology reaches its limits, especially in the case of quiet, cold or difficult-to-access leaks. FlowBOS works reliably even where neither ultrasound nor IR cameras provide a signal. The system is therefore a precise and scalable alternative for safety-critical applications with H₂ or NH₃.

Find the right camera for your requirements now!

Precise measurement technology is crucial for using alternative fuels efficiently, safely and economically. LaVision offers highly developed optical measurement methods for the detailed analysis of combustion processes, flows and possible leaks.

Frequently asked questions (FAQs)

for leakage detection with FlowBOS

How does FlowBOS leakage detection work?

FlowBOS uses optical flow analysis to make air turbulence visible. This enables non-contact and precise visualization of leaks.

Which leaks can FlowBOS detect?

The system detects both “micro-leaks” and larger leaks in tanks, pipes, valves and industrial plants.

Is measurement also possible during ongoing production processes?

Can FlowBOS detect hydrogen and ammonia leaks?

Yes, our technology enables highly sensitive visualization of these invisible gases without chemical markers or sensors.

How complex is the integration of FlowBOS into existing quality systems?

FlowBOS can be used flexibly and can be easily integrated into existing production and safety processes.