See, analyze and optimize flowsMaking invisible air and gas flows visible - for controlled processes

Making the invisible visible - this is how LaVision enables process reliability

In the world of fluid mechanics, precise flow visualization is crucial for research, development and industrial applications. Air flows, temperature distributions and gas dispersions are invisible to the naked eye, but have a significant impact on the efficiency and safety of products and processes. With its highly developed FlowBOS systems, LaVision offers an innovative solution to make these invisible flows visible and measurable in real time – contactless, highly precise and without contaminating tracer materials.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationInstead of talking about abstract expertise, we let the results speak for themselves. Our customers benefit from a close partnership that goes far beyond the purchase of equipment. Tailor-made advice – from selecting the right measuring system to optimizing integration into your processes. For more than three decades, LaVision has been developing and supporting its market partners on an equal footing – worldwide and with a practical focus Sophisticated technology that works in real time and brings measurable added value to your company.

LaVision - Your partner for optical excellence in flow visualization

The advantages of flow visualization with LaVision

Our imaging systems are based on Background Oriented Schlieren (BOS) to capture flows in unprecedented detail.

Wide range of possible uses & fields of application

Making hydrogen visible

Ammonia leakage detection & flow analysis

Ammonia is becoming increasingly important as a carbon-free alternative in shipping and industry. Our FlowBOS systems enable reliable detection of ammonia flows and leaks in order to minimize environmental risks and optimize industrial processes.

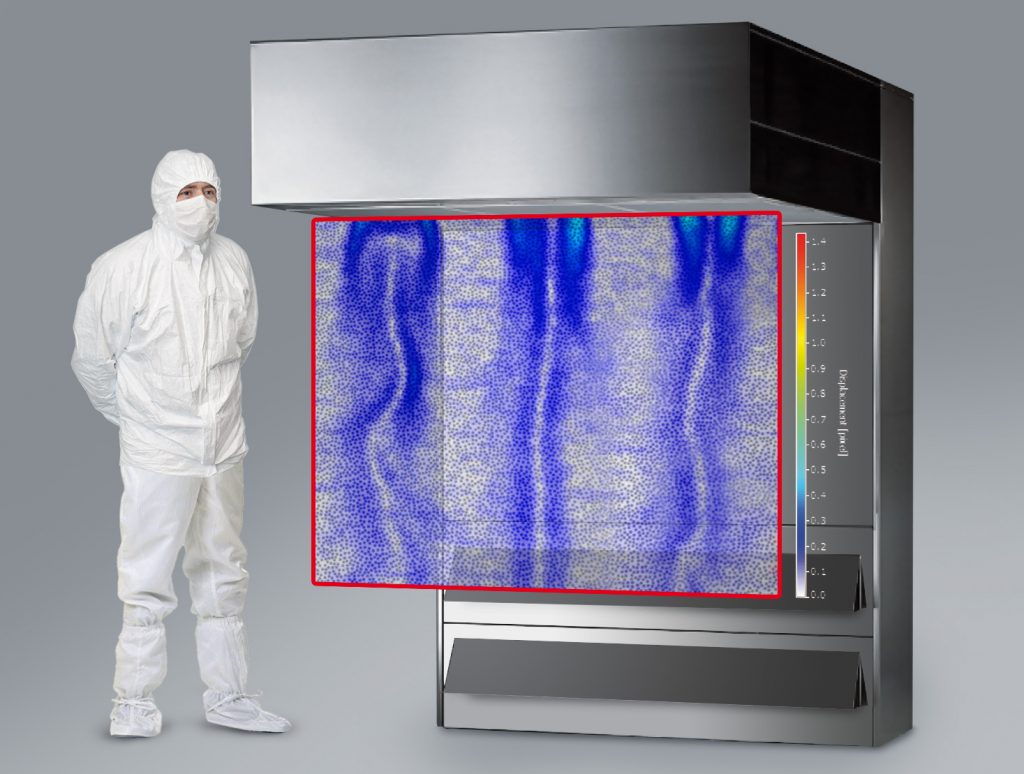

Cleanroom measurement technology - Particle-free flow analysis

Contamination-free flow measurements are essential in sensitive production environments such as semiconductor manufacturing or the pharmaceutical industry. With FlowBOS systems, air flows can be made visible without contamination in order to optimize existing cleanroom conditions.

Detection of leaks

Whether in industrial gas pipelines, hydrogen storage facilities or other gas production sites – even the smallest leaks can have serious consequences. FlowBOS enables the fast, non-contact detection and localization of leaks, even in large-scale industrial plants or kilometre-long pipelines and even in battery storage facilities.

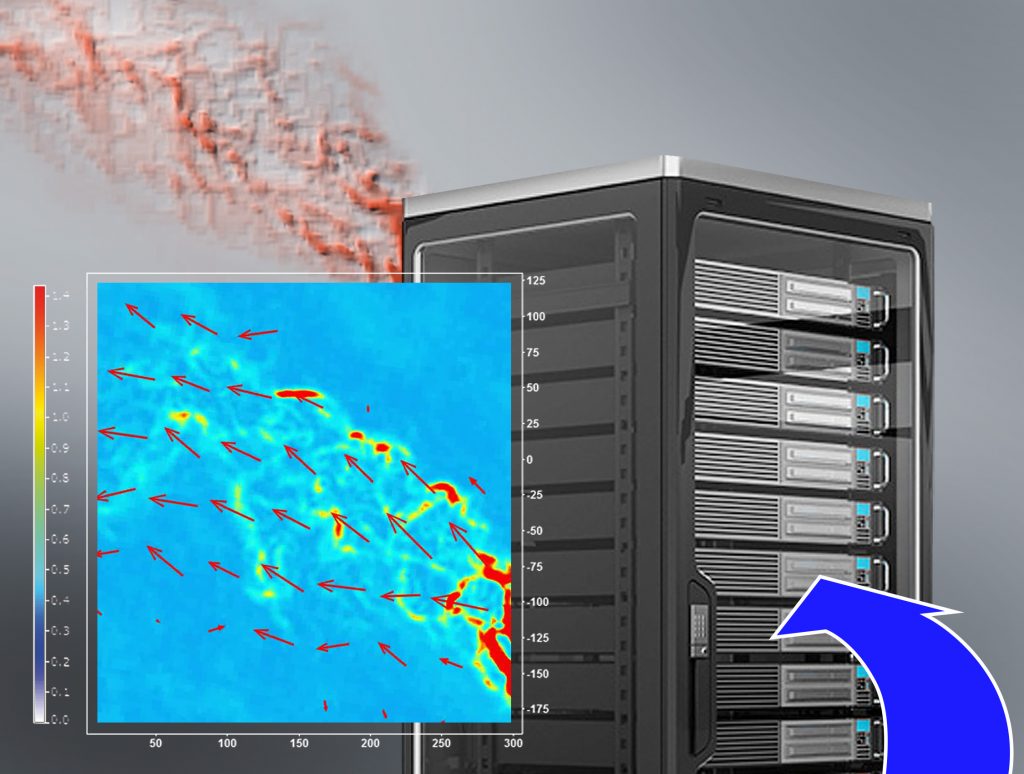

Thermal flow visualization

Visualization and analysis of invisible air and gas flows - FlowBOS makes it easy

Maximum data quality through intelligent image processing

The innovative FlowBOS camera systems from LaVision provide easy-to-understand flow analyses and are simple and intuitive to operate. They process the images in real time, analyze flow patterns and enable a detailed evaluation of density, temperature and velocity distributions in gases.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Automatic recording and processing of flow patterns

- Detailed analysis of flow patterns with intelligent image correlation

- Support for FlowBOS, imaging measurement techniques

- Live visualization for immediate evaluation of flow dynamics

Advanced algorithms for more precise measurement results

- Correction of diffraction effects, distortions and lighting inhomogeneities

- Real-time calculation of density and temperature fields from optical flow images

- Integrated Schlieren and BOS analysis for gaseous flows

- Modularly adaptable for various research applications

- Export options for industry and research reports

Intuitive control with maximum control

- Intuitive touch interface: optimized for fast operation directly on the screen, even when wearing gloves

- Live overlay: The measuring system combines the camera image with the analyzed flow curve in real time – for maximum informative value

- Video recording with one click: All live data can be recorded, documented and analyzed directly

- Efficient workflow: Ideal for quick setups, flexible test setups and standardized test processes.

FlowBOS - convincing advantages

Enables contactless visualization of gas and air flows without aerosols

Industries & areas of application

The analysis of air and gas flows is of great importance for many core industries and supports research, quality assurance and efficiency improvements.

The FlowBOS camera family

Visualizing measurement technology is crucial for analysing and optimizing air and gas flows. With our FlowBOS camera family, you will always find the right model for your specific application.

Standard design

- Single camera

- Interchangeable lens

- Detachable tablet

- IP44 housing

- Robustness

- Flexibility

Large distance design

- Stereo camera

- Interchangeable lenses

- Detachable tablet

- IP44 housing

- Robustness

- Flexibility

Frequently asked questions (FAQs) about flow visualization with LaVision FlowBOS

Why is the visualization of flows so important?

What advantages does the FlowBOS system offer compared to conventional methods?

FlowBOS enables particle-free, non-contact and contamination-free flow measurement. In contrast to conventional smoke or aerosol-based methods, our system detects flows using particle-free tracer gas, which is ideal for cleanroom and industrial applications, for example.

Can the FlowBOS system also be used to detect leaks?

Which gases and flows can be visualized with the LaVision systems?

Our technology enables the visualization of almost all gases and thermal flows, including hydrogen, ammonia, air flows in clean rooms, vehicle air conditioning and waste heat air transfer in industrial processes.

How can LaVision support companies and research institutions in flow analysis?

How is the measurement data from the FlowBOS cameras recorded and evaluated?

The FlowBOS cameras provide high-resolution flow visualizations in real time. The recorded data is processed in real time, the flows are digitally analyzed, deflection patterns are calculated and precise density and temperature distributions are derived. These evaluations can be used directly for scientific studies, process optimization or quality control.

Making invisible air and gas flows

visible for your processes!

With our innovative measurement technology, we can create individual solutions for your industry in your applications.