See every drop. Optimize every spray application. Maximize the success of cosmetic and household sprays

LaVision - Scientific precision for optimum spraying results for your products

The quality of a spray product determines its efficiency, cost-effectiveness and customer satisfaction. A faulty spray pattern or uneven droplet distribution can reduce effectiveness, lead to increased material consumption or have a negative impact on the application experience. We use precise optical measurement methods to analyze spray patterns, spray cones and droplet distributions at the highest level of detail. This data helps manufacturers to optimize product formulation, spray technology and application processes in a targeted manner – from development to production. Our systems deliver reliable, reproducible results and enable precise dosing, optimized spraying processes and consistent quality.

Household spray Imaging

Quality and efficiency for care products

Our optical measurement techniques precisely analyze the spray pattern, dosage and behavior of aerosols – both water-based and alcohol-based as well as at different viscosities. Automated real-time analyses save time in development, improve production processes and increase the market opportunities of your household products.

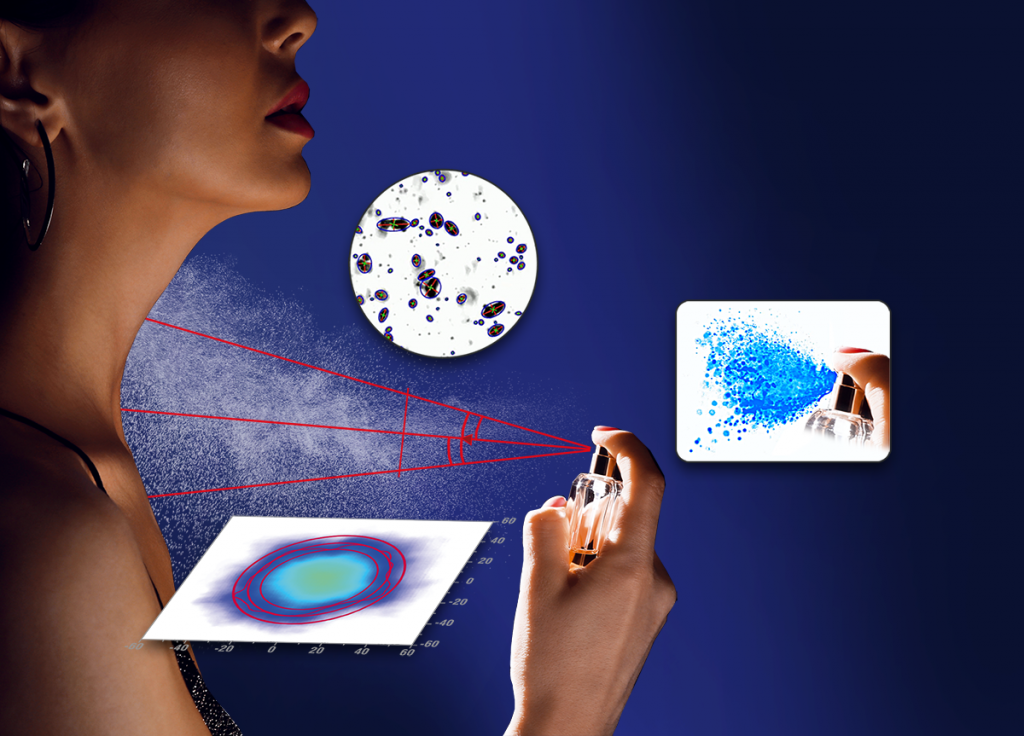

Cosmetic spray Imaging

Perfection for an exceptional application experience

We analyze the spray behavior and dosage of products such as deodorants, hairsprays and perfumes to ensure an optimal cosmetic application experience. Time-resolved measurements enable precise adjustment of aerosols (water-, oil- or alcohol-based) as well as liquids and powders – for consistently high product quality and maximum customer satisfaction.

Detailed optical analysis for complete spray characterization

In order to the physical properties and behavior of a spray, we usewe use the most modern optical measuring methods a. These methods enable a detailed visualization and quantification of the spraying processes – from the development of the spray shape to the droplet distribution.

These methods provide manufacturers with practical, quantitative data to improve their spraying processes in a targeted manner and ensure quality in the long term.

1. spray pattern analysis

- Measurement of spray geometry: homogeneity, size, shape and uniformity of the spray

- Dynamic representation: temporal development of the spray pattern using high-resolution image sequences

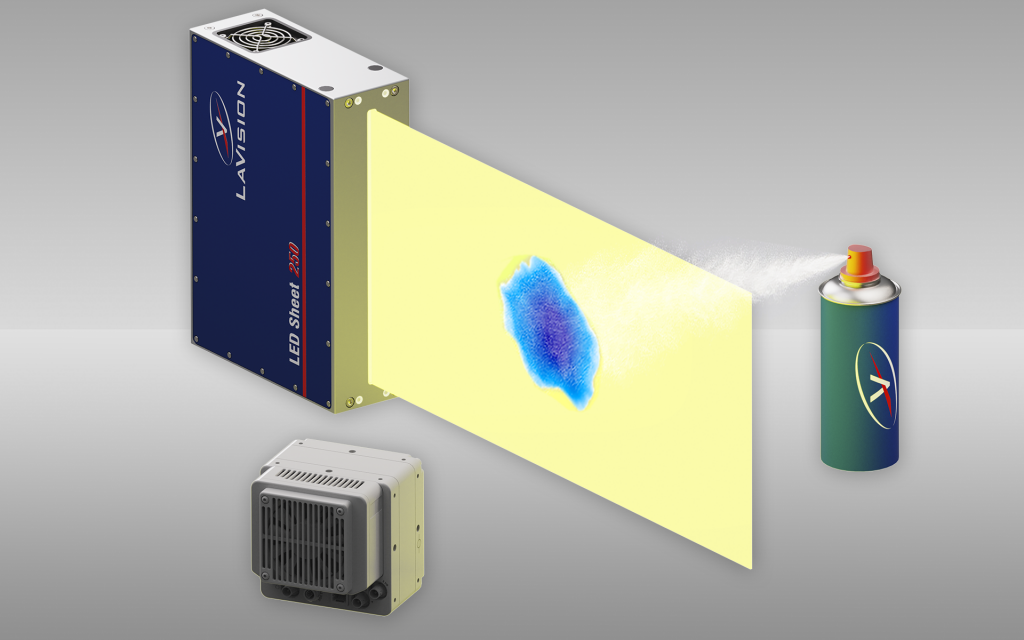

Measuring method

Lateral light sheet illumination for precise detection of the spray pattern at any distance from the spray outlet.

2. analysis of the spray cone / spray plume

- Measurement of distribution: angle, penetration depth and uniformity for clean application

- Dynamic visualization: Development of the spray cone with high-speed measuring method

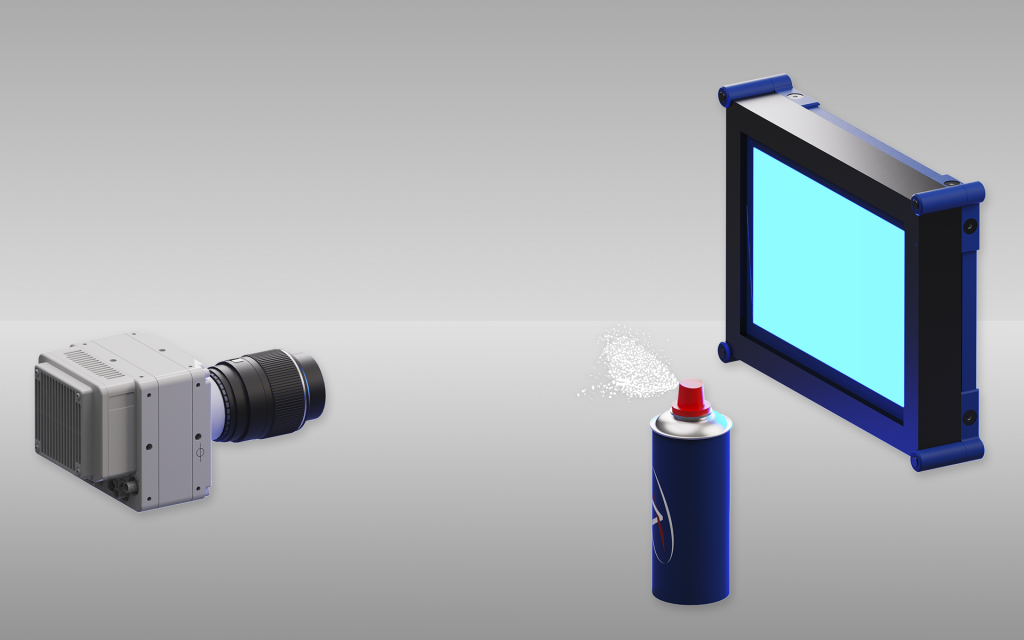

Measuring method

Precise spray cone measurement thanks to backlighting

3. spray break-up detection (high-speed)

- Illustration of droplet formation: Splitting of the liquid

- Goal: Optimization of the mechanics for finer distribution

Measuring method

Backlit high-speed images for detailed spray structure detection

4. droplet size and distribution analysis

- Measurement of the droplet size distribution, e.g. DV50

- Evaluation of homogeneity for uniform product application

Measuring method

LED-based shadowgraph images for high-resolution droplet recording

Innovative optical analysis methods for complete spray characterization

Our measuring systems record all relevant parameters – from the research laboratory to series production. We use optical methods to precisely analyze spray patterns, spray cones and droplet sizes. The data is evaluated with software support and forms the basis for well-founded decisions along your entire process chain.

In our test procedures, we examine key product properties:

- Formulation: influence on droplet size and distribution

- Container design & material: Influence on flow and dosing

- Spraying mechanism & pressure ratios: Atomization and function

Possible applications along your product life cycle

Research and development (R&D) and product design

- Quick adaptation to different container sizes and technologies

- Flexible configuration for various measured variables and parameters

- Objective comparability and high reproducibility

Quality assurance (QC): Reliable test series in protected test rooms

- Automated analysis processes to increase efficiency

- Data can be integrated into existing QA systems

- Early detection of deviations to avoid errors

Production: real-time measurements for process control

- Continuous monitoring of the spray quality

- Immediate adjustment in the event of deviations

- Long-term optimization through trend analyses

Comprehensive support from development to series production.

Our technologies accompany you through the entire product life cycle – precisely, efficiently and with a clear focus on quality.

Make sure you get individual

expert advice!

Optimize your spraying processes with precise measurement technology – from development to series production. Our experts will help you find the right solution for your requirements. Contact us now for a no-obligation consultation!