Make distribution visible. Check layer quality.

Increase product performance.

Research & development for paint sprays, paints and coatings

Research for perfect results

for paint spraying, painting and coating

The quality of a paint or coating is crucial for the protection, appearance and durability of a product. In R&D, paint sprays, paints and coatings must be optimally matched to the respective substrates, material losses must be minimized and spray processes must be precisely controlled. LaVision offers leading optical measurement systems that enable scientists and developers to analyze spray behavior in detail, optimize application mechanisms and develop the best formulations for their applications.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationLaVision stands for many years of expertise in supporting research and product development

With over three decades of experience in high-precision metrology, LaVision works with the world’s leading manufacturers to make painting and coating processes more efficient, reproducible and sustainable. Our imaging systems provide detailed data from the initial development phase through to product optimization and help to significantly shorten research cycles.

Digital data and process visualizations available to you for research and product design

Accurate measured values thanks to innovative algorithms of the DaVis software

Innovative optical measurements are the basis for the quality of results - your benefits

- Optimization of spraying processes and patterns for improved product quality

- Increased efficiency through sound data evaluation – reduces development time and testing effort

- Development of sustainable spraying processes by minimizing material consumption and overspray

- Early detection and correction of formulation and application errors

- Higher product quality – Uniform and reproducible layer thicknesses & surfaces

- Reducing development times – digital data analysis for faster processes

- Collaborative working thanks to the free DaVis viewer

- Documentation from the first attempt

- More efficient process design – faster adjustments thanks to precise, reproducible measured values

- Safety & conformity to standards – measured values as proof for product approvals and regulatory requirements

Our visual measurement methods capture detailed data for your research and product development:

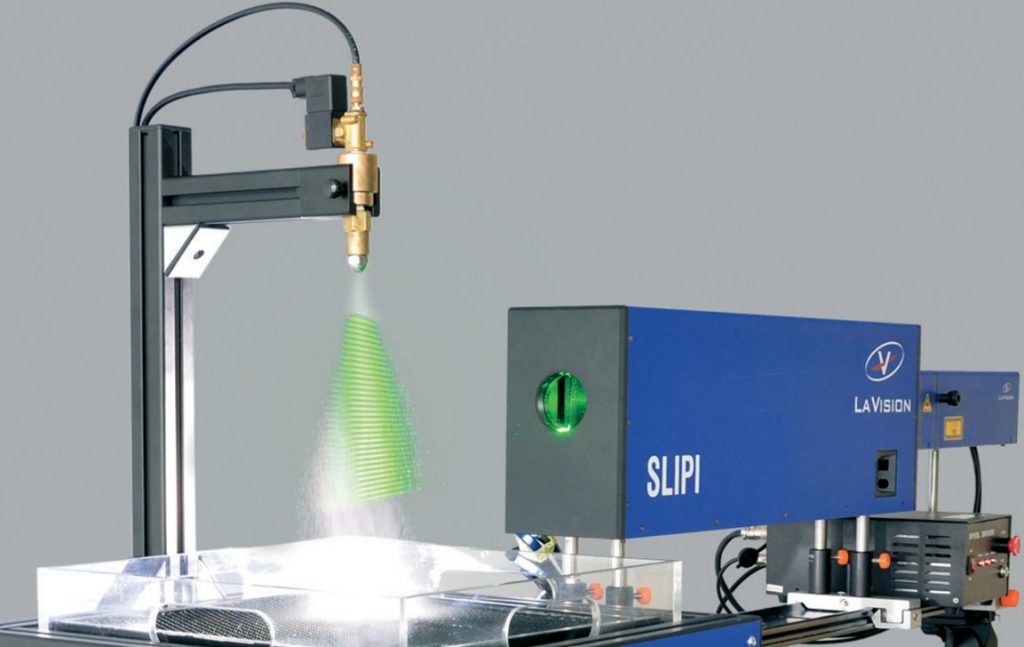

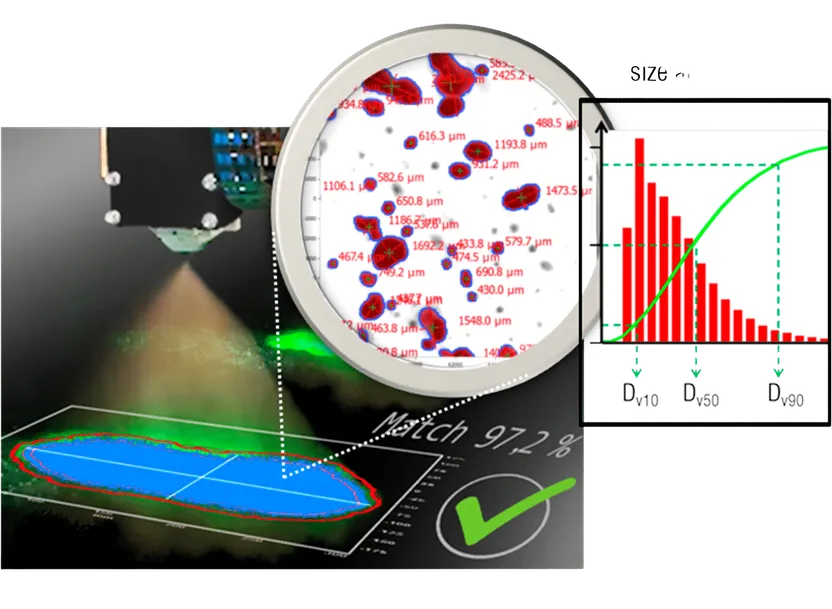

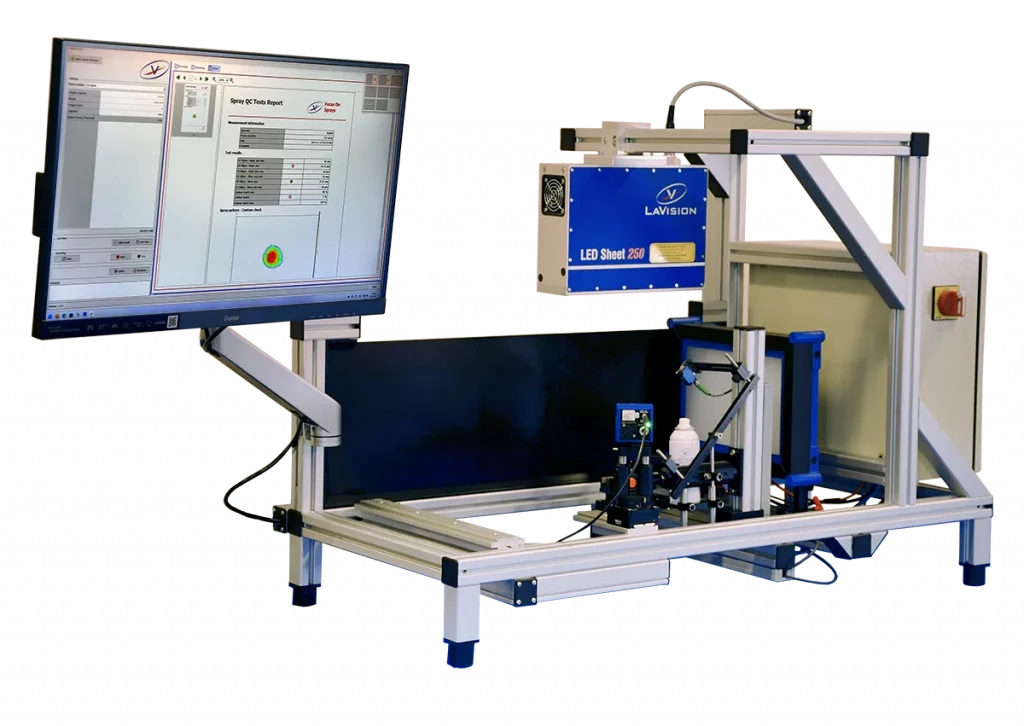

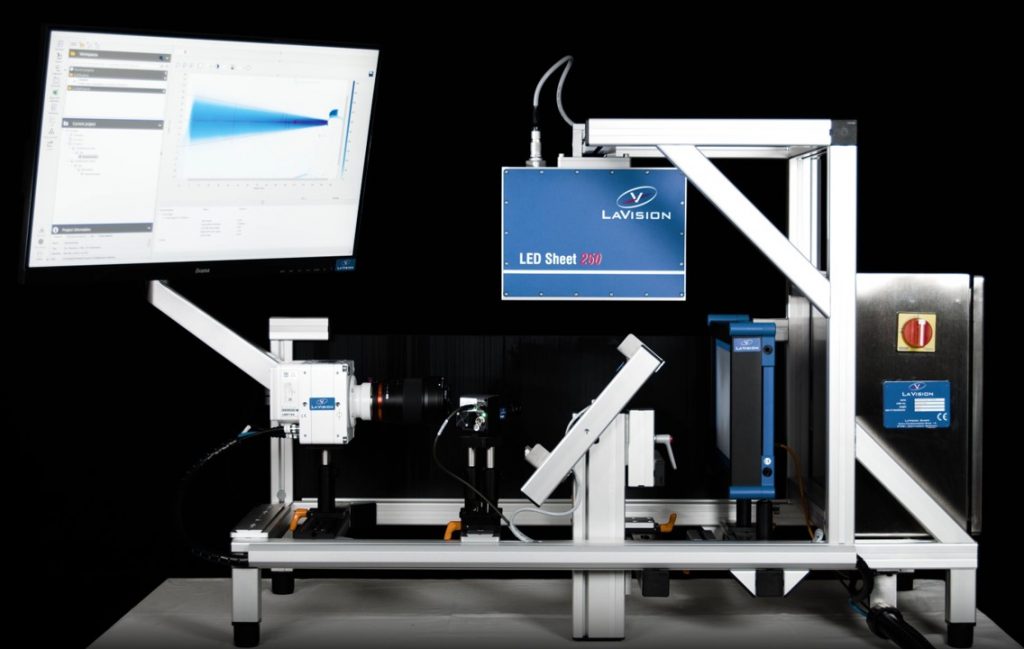

SprayMaster inspex

The versatile optical measuring system for spray analyses

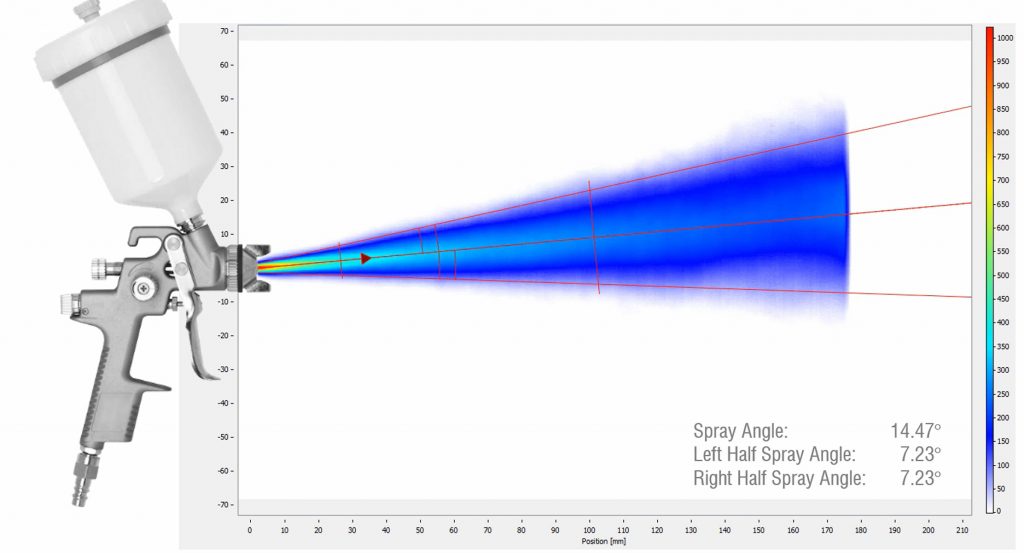

- Spray pattern geometry:

Homogeneity, size, shape & uniformity of the coating - Spray cone analysis:

Angle, penetration depth & distribution for perfect applications

Our universal system for spray research

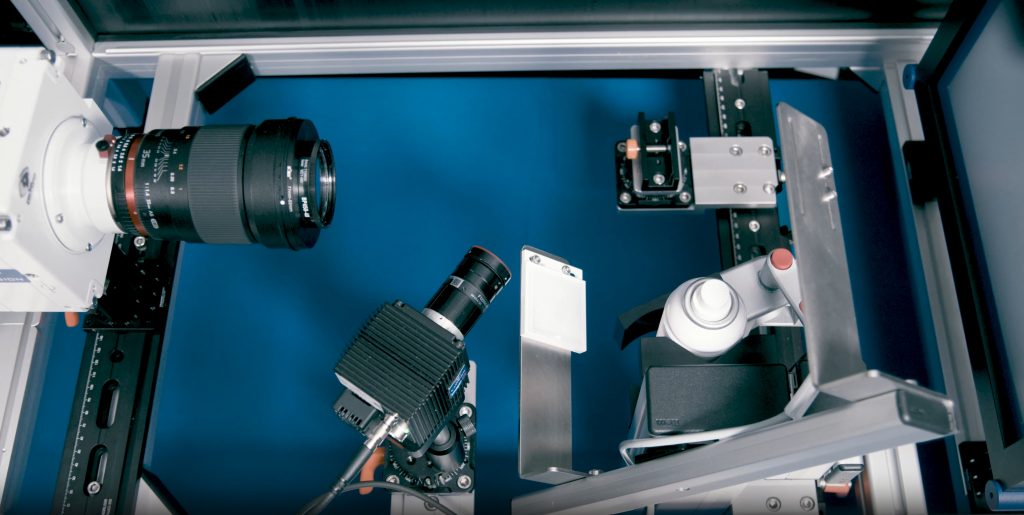

System & components

Measured variables & analysis areas

The spray cone influences the application efficiency and the subsequent homogeneity of the painted and coated surfaces. The system precisely measures the cone angle, the penetration depth and the symmetry of the spray jet to ensure optimum spray distribution for different application areas.

Modularity & flexibility

- Universal holder – Adaptable for various spray nozzles, spray bottles and other applicators

- Quick change between measuring tasks – Flexible adjustment for different test methods and formats

- Expandability – Additional modules for specific measurements such as droplet size distributions or spray characterization

- Flexible configuration – adaptation of test setups for different liquids and spray systems

- Easy integration – compatible with high-speed cameras, additional sensors and other analysis modules

- Long-term investment security – scalable system that grows with new research requirements

Advantages for spray research & development

- Highest accuracy – scientifically based measurement methods for precise spray characterization

- Digital & reproducible results – comparability with reference test images for consistent quality assurance

- Automatic test reports – efficient documentation and archiving of all measured values

- Detailed measured values – thanks to innovative algorithms in the DaVis software

- Collaborative working – support from the powerful DaVis software, including free DaVis Viewer

- Can be used in various test environments – inline, atline, online or offline for maximum flexibility

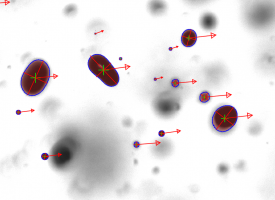

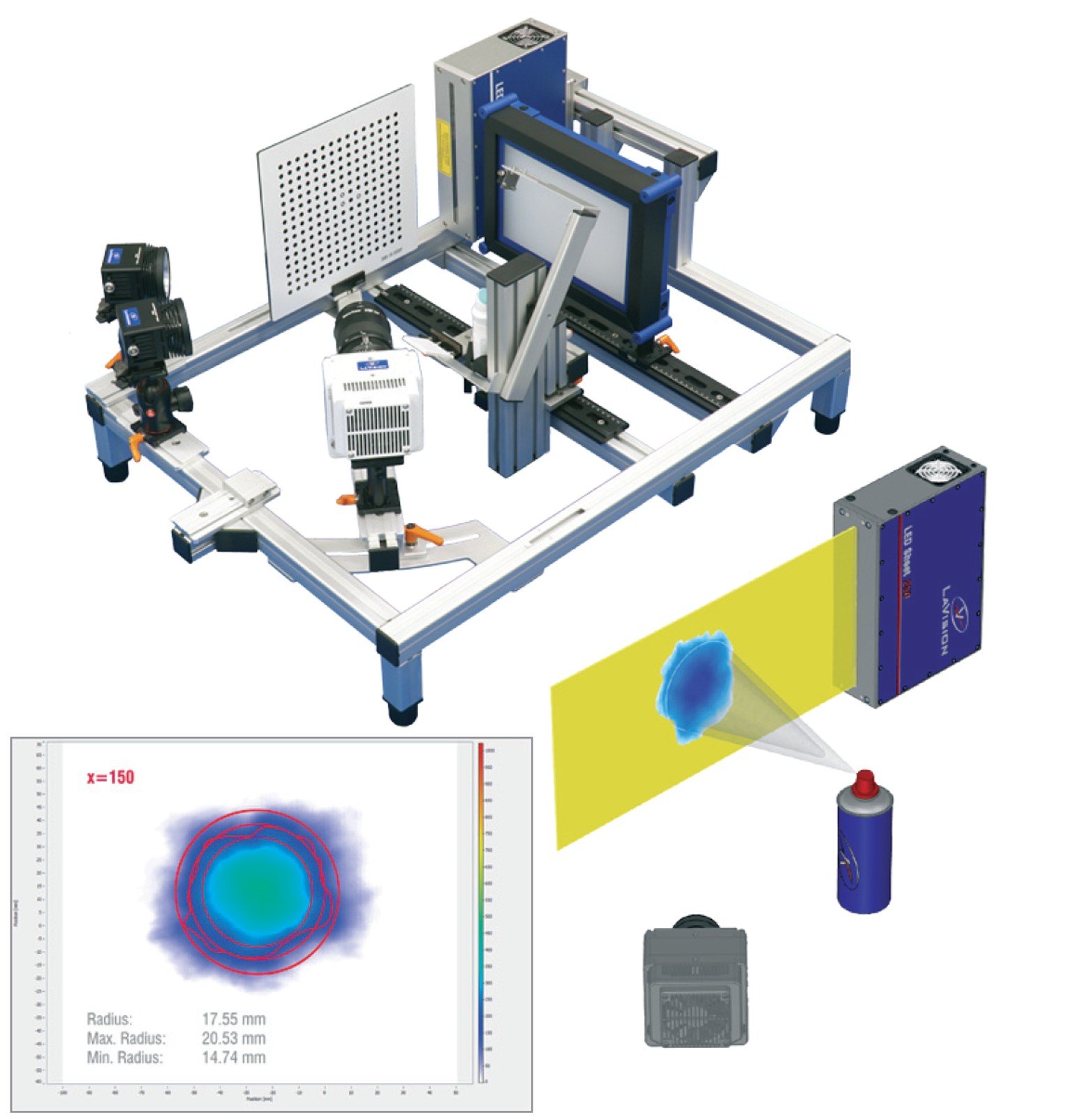

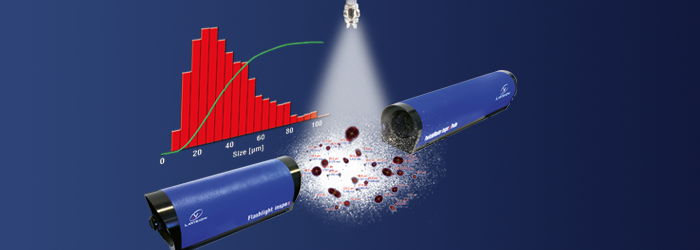

ParticleMaster inspex

Precise particle & droplet size analysis

- Droplet size & distribution – Detailed analysis of particle density & droplet sizes

- Particle homogeneity – optimization of uniformity & density for precise coating layers

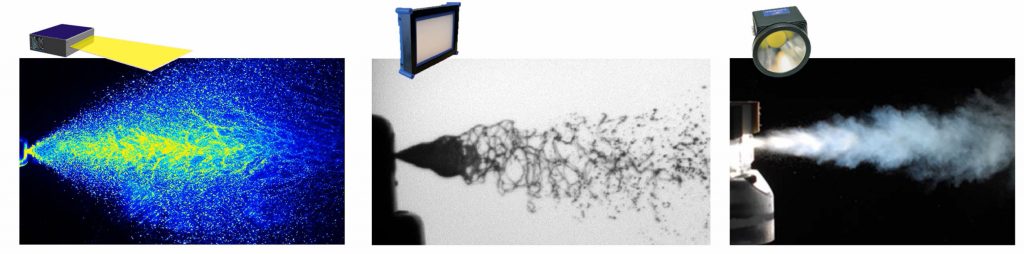

- LED-based shadowgraph analysis – Highest precision for particle measurements

- Flexibly expandable system – Adaptable to different liquids & application methods

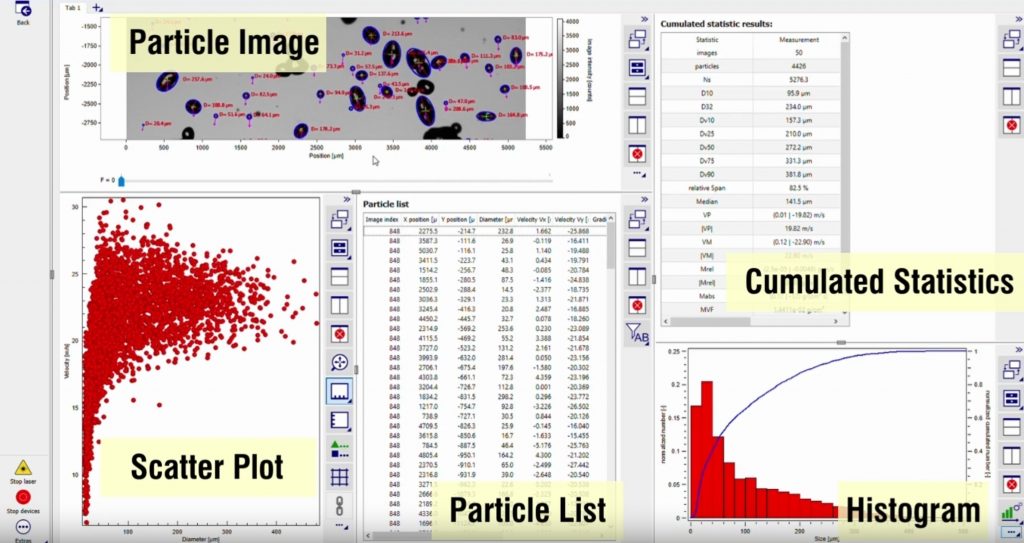

- Digital data evaluation – Automated analysis & real-time visualization

Innovative paint coating and spray research

System & components

The ParticleMaster inspex uses LED-based shadowgraph imaging for high-resolution droplet analysis. The light source and sample are placed outside the spray area, which means that electrical components do not come into contact with the spray. The high-resolution camera system in the sample precisely records the droplet size, speed and shape. The dynamic image analysis (DIA) evaluates the recorded images and guarantees operator-independent, reproducible results in the shortest possible time.

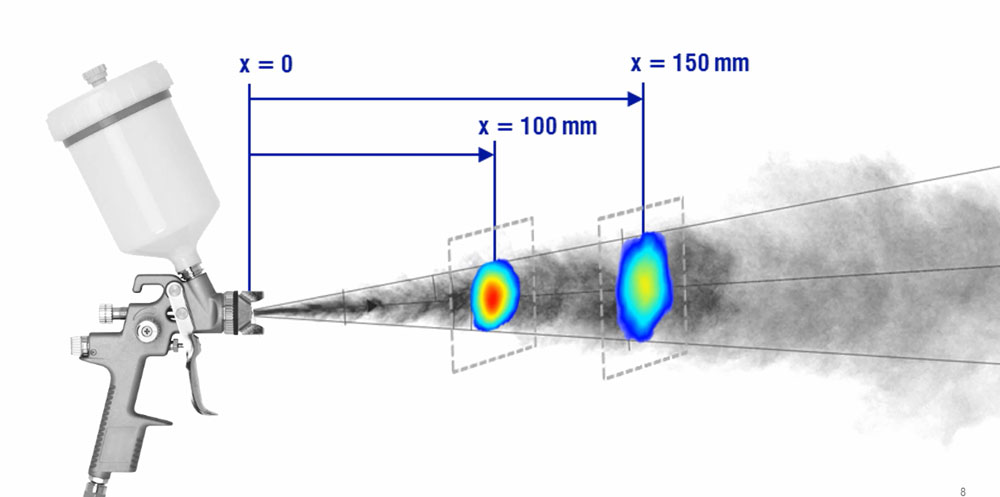

Measured variables & analysis areas

- Particle concentration: Number and mass concentration within the spray jet

- Particle homogeneity: shape, density and uniformity across the spray cross-section

- Particle size distribution spectrum: Detection of minimum to maximum diameters between 10 – 2,500 µm depending on equipment model and application

- Spray density profiles: Distribution of particle concentration over the width and depth of the spray

- Particle velocity (optional for combined measurement): Velocity and dynamic distribution of individual particle droplets.These measured variables enable precise quality control and process optimization in product development.

Modularity & flexibility

- Expandable system: Additional modules for measuring different particle sizes and concentrations

- Flexible configuration: Adaptation to different measuring tasks for paint sprays, paints and coatings

- Modular expandability: flexibly adaptable for different particle size ranges and applications

- Combination capability: can be seamlessly combined with other LaVision systems such as SprayMaster or high-speed imaging solutions – for comprehensive, synchronized spray analysis

- Variable measuring ranges: Selection of different optics and detector modules for adaptation to individual test setups

- Easy integration: quick and tool-free system configuration for changing measurement setups in laboratory and production environments

- Investment security: thanks to its modular design, the ParticleMaster inspex can be expanded with additional components at any time to meet future requirements

Advantages for spray research & development

- Highest precision – Scientifically sound measuring methods for exact droplet and particle analysis

- Digital & reproducible results – comparability with reference values for consistent quality assurance

- Automated data acquisition & evaluation – Efficient analysis with powerful DaVis software

- Can be used in various test environments – inline, atline, online or offline for maximum flexibility

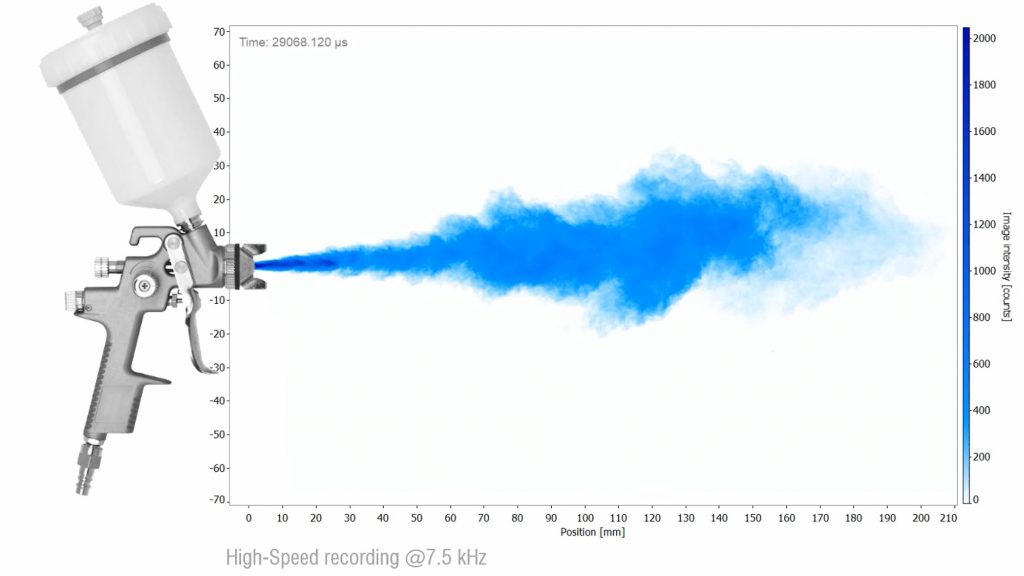

High-speed cameras - making spray break-up visible in real time

Our high-speed cameras record the development of the spray mist over time at the highest frame rate. They enable a detailed analysis of the spray atomization and the break-up of individual droplets – ideal for optimizing dosing and application processes.

- Real-time visualization:

High-speed images for a complete analysis of the spraying process - Detecting the smallest particle movements:

Investigating critical phases of spray break-up in detail - Flexible integration:

Combination with other LaVision measurement systems for comprehensive analyses

The next generation of spray diagnostics

Discover more information about our innovative measuring systems on our research portal:

PIV

Particle Image Velocimetry

Flow analysis with high-resolution recording of velocity and vortex structures

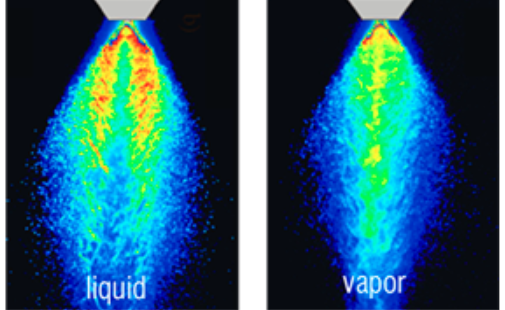

LIF

Laser Induced Fluorescence

Analysis of droplet size distributions and visualization of liquid and vapor phase with tracer LIF method

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationEfficiency and reproducibility

in product development

Thanks to the powerful DaVis software, our measuring systems offer reproducible and precise results. The innovative algorithm ensures that measured values are accurate and reliable, which significantly speeds up development cycles. The ability to analyze and compare different spray patterns enables the development of innovative products with optimum properties.

Shorter development times and perfect

coating results

Optimize your painting and coating products with precise measurement technology – from development to series production. Our experts will help you find the right solution for your requirements.

Contact us now for a no-obligation consultation!