Detailed spray diagnostics. Perfect distribution.

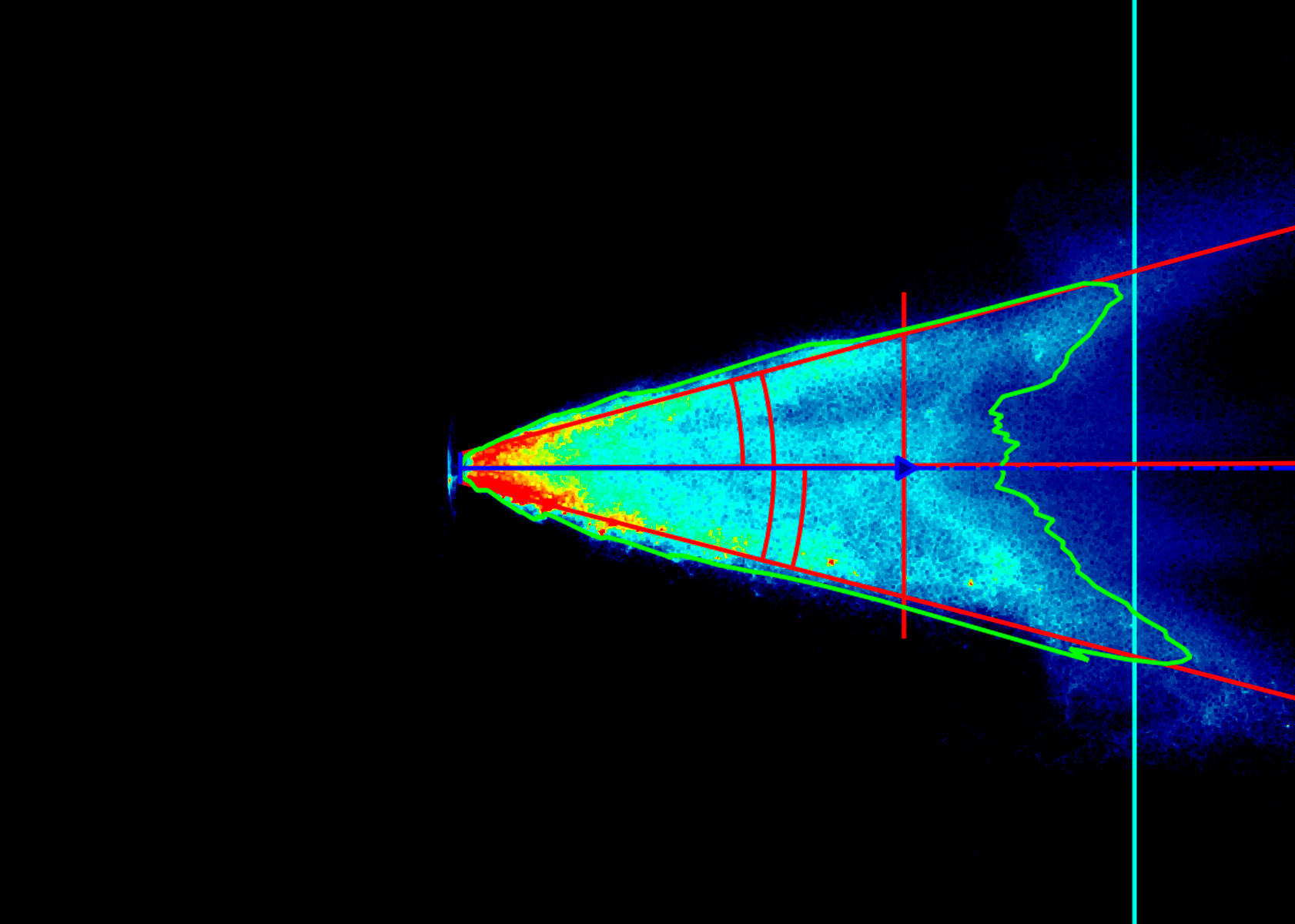

Maximum quality.Analyze spray shape and angle. Assess uniformity and distribution. Optimize spray performance.

Precision for every spraying application - optical measurements that impress in detail

LaVision’s highly developed optical processes give you in-depth insights into your processes. Our systems enable precise analyses, targeted optimization and continuous monitoring in production. This allows you to develop products of the highest quality, increase your efficiency and impressively visualize new technologies – for sustainable market success.

Innovative solutions for your spray analyses

LaVision is a world leader in the visualization and analysis of spray images. Our systems, developed and configured in Göttingen, provide research and industry with the optimum basis for precise spray analysis. Whether online, inline, atline or offline – our technologies enable the digital capture and precise measurement of spray structures, both in real time and in post-processing. With decades of experience and innovative approaches, we ensure reliable results and a wide range of applications.

Optimized spraying systems for maximum efficiency and quality

Spray systems are often regarded as a simple technology – as long as a nozzle sprays, the process seems to work. In practice, however, small deviations lead to major quality losses and unnecessary waste of resources. As spray nozzles are designed for clearly defined conditions, regular inspection is essential. Optimizing your spray systems is essential to reduce operating costs and sustainably improve processes.

- Improved product and process quality thanks to consistent, defined spraying performance.

- Higher customer satisfaction through consistent results.

- Efficient operation without unplanned downtimes.

- Reduction of water, chemical and energy consumption.

- Sustainable use of resources to protect the environment.

Complete solutions for industry and research

Our optical measurement systems combine modern hardware with the powerful DaVis software. This offers a wide range of display and analysis options for your spray data. Results can be shared quickly and securely via the DaVis Viewer. Whether for development, quality assurance or production – our complete solutions improve processes, reduce costs and increase operational reliability.

Every drop of perfection -

Advanced Spray Diagnostics

Optimizing spray technology is crucial to maximize efficiency, conserve resources and ensure the highest product quality through precise control and analysis of each droplet.

Perfecting household & cosmetic sprays

Spray analysis for paints and coatings

Optical measurements of injection systems and fuel sprays

Quality is never a coincidence! It is always the result of ambitious goals, sincere effort, an intelligent approach and skillful, continuous measurement of one's own results.

5 reasons why spray diagnostics

are indispensable

Why is precise spray diagnostics so important?

It provides detailed data on droplet size, distribution and speed. This information forms the basis for efficient processes, reduced reject rates and consistently high product quality.

How does spray diagnostics improve product development?

It helps to precisely coordinate spraying processes. This allows innovations to be implemented in a more targeted manner and development processes to be significantly accelerated – for example in the automotive, cosmetics or pharmaceutical industries.

What role does spray diagnostics play in production?

It ensures that spraying processes remain stable. Deviations are detected and corrected immediately. This ensures quality standards and reduces production errors.

How does spray diagnostics contribute to sustainability?

Optimized spraying processes save liquids, chemicals and energy. This reduces the consumption of resources while maintaining product quality.

In which sectors is spray diagnostics particularly important?

In the automotive industry (e.g. injection systems), in the pharmaceutical and cosmetics industry (e.g. aerosols) and in paint and coatings technology. There it ensures reliable results with the highest requirements.