Reliable testing. Coat evenly.

Ensure production quality.Optical measurement solutions for online control of industrial spraying processes

Leading in the optical analysis of coatings and paintwork

A new approach to quality control - fully automated measurements for maximum production reliability

Increase the efficiency and precision of your production with intelligent, fully automated quality controls. Our innovative measuring systems enable reliable online monitoring and analysis of all spraying processes in real time. This allows you to minimize errors, reduce rejects and ensure the consistently high quality of your products – without any additional effort.

Online quality testing of paint sprays, paints and coatings ensures optimum spray properties.

Integrated high-tech measuring systems guarantee consistently high surface quality.

Inline and atline-capable optical measurement technologies for the highest product quality.

Automatic recording, analysis and evaluation of spray parameters during production.

Reduction of manual testing efforts through seamless integration into production lines.

Automatic process adjustment – direct correction in production in the event of quality deviations.

Complete documentation & traceability – Fully integrated digital recording of all measurement results.

Connection to databases and production control – integration into your environment for maximum efficiency.

LaVision - Your partner for automated

online QC measurements worldwide

- Over three decades of experience in industrial measurement technology

- Measurement technology partner to leading automotive manufacturers and machine builders

- Technology leader in optical precision measurement for spray and coating technologies

- Customized solutions for online, inline and atline quality controls

Overview of the measurement methods used

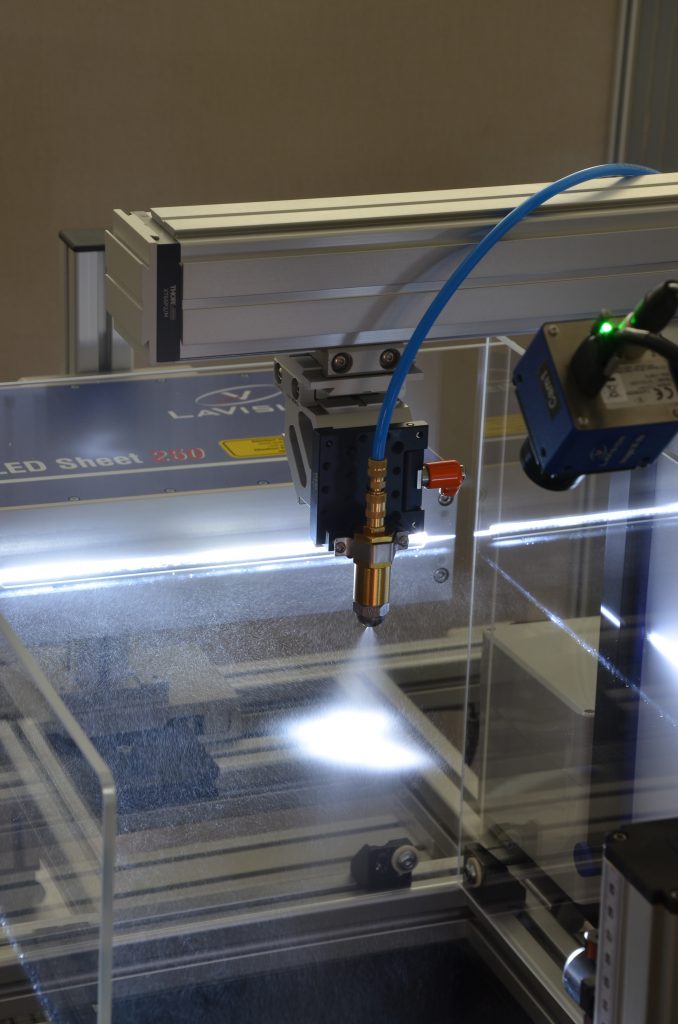

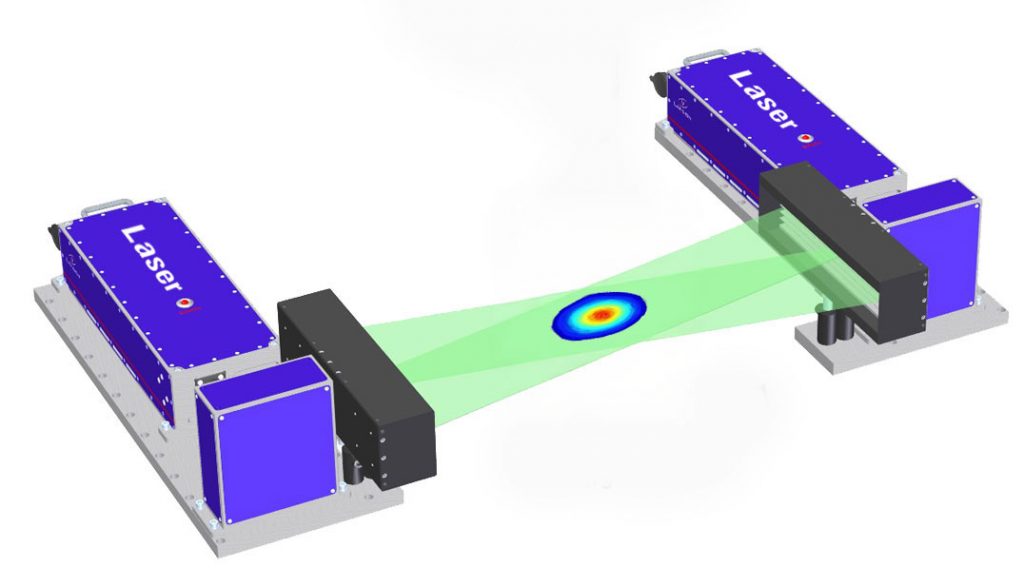

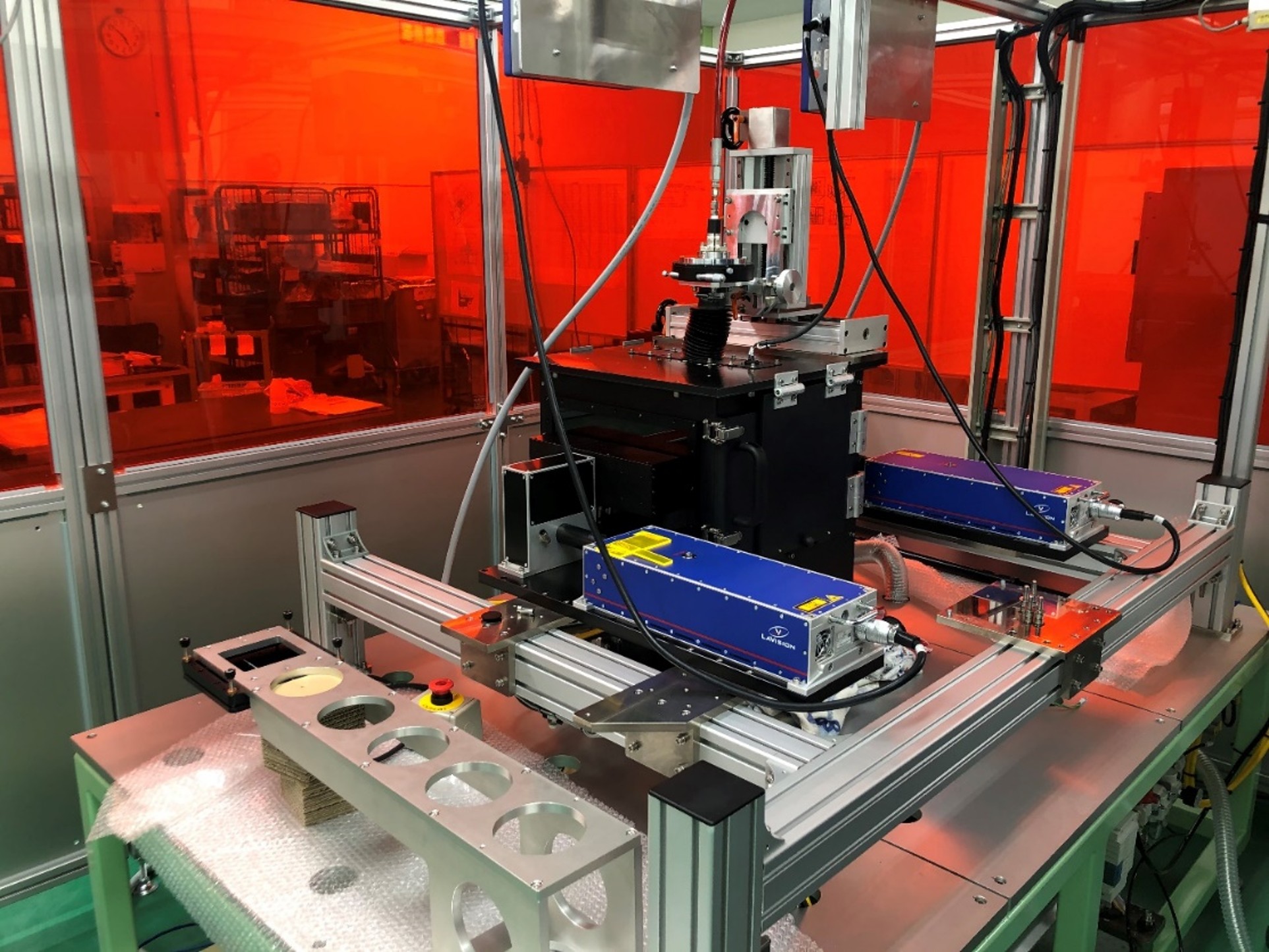

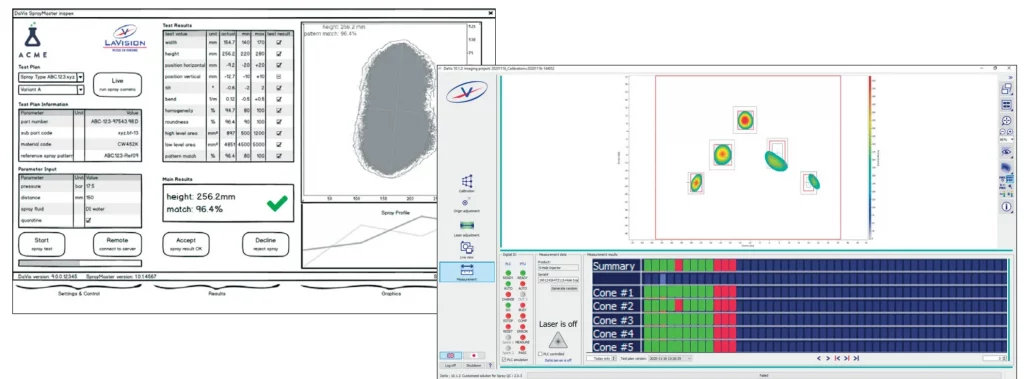

SprayMaster inspex

The high-performance system for online quality monitoring

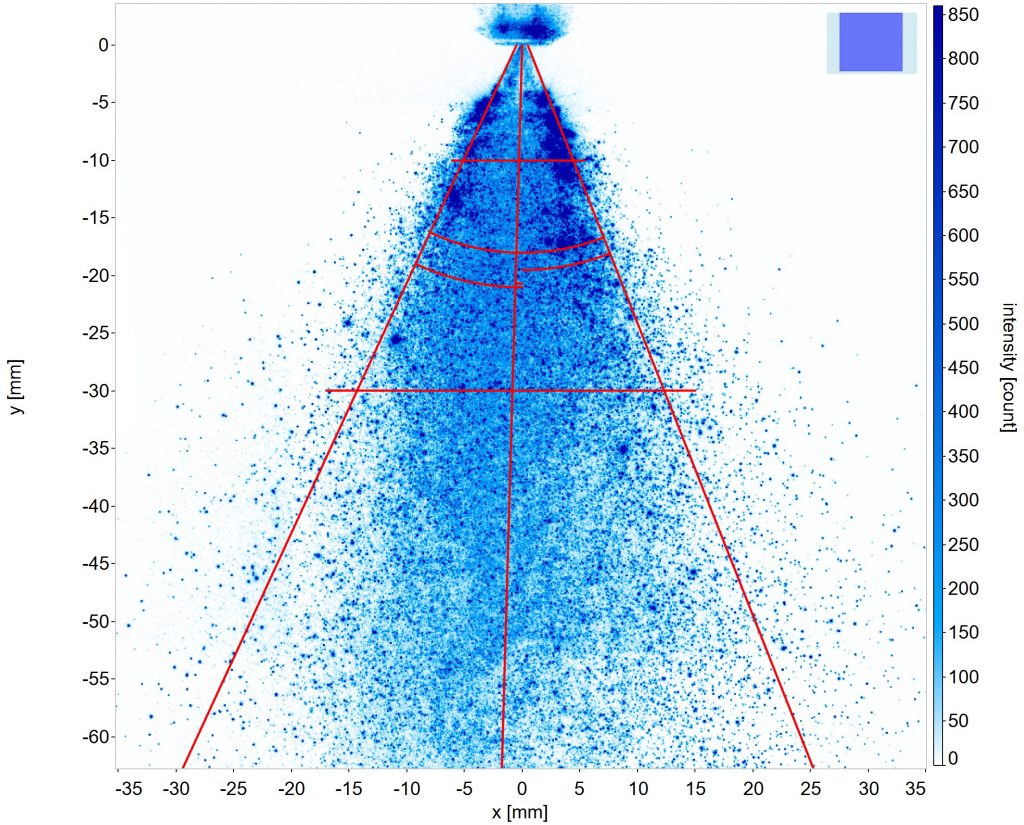

The innovative optical measuring process enables detailed analysis of the spray pattern and spray cone to ensure product quality directly in the production process. With its high flexibility and expandability, the system adapts to individual production requirements – for consistently documented and assured quality during paint spraying, painting and coating in the production line.

System & components

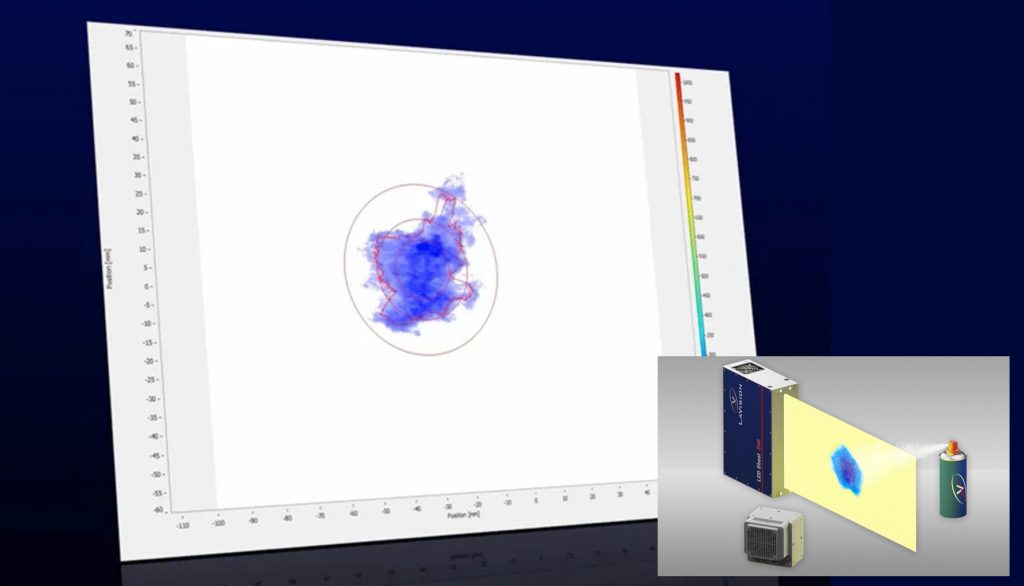

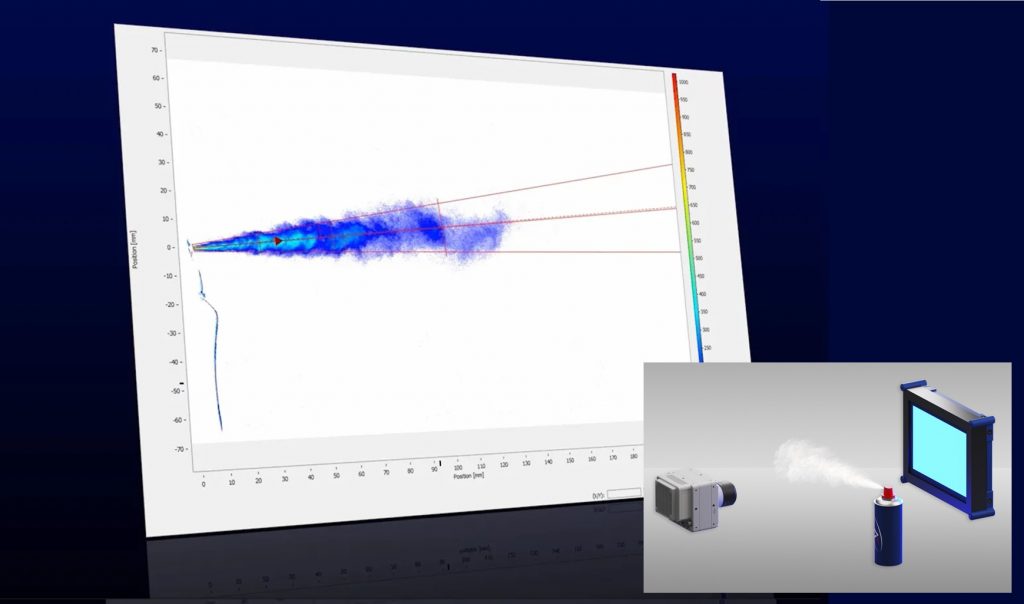

Measured variables & analysis areas

Spray cone analysis: The spray cone influences application efficiency and the user experience. The system precisely measures the cone angle, penetration depth and symmetry of the spray jet to ensure optimum spray distribution for different application areas.

Optimized for inline applications

- Continuous control: Reliable measuring methods for continuous monitoring of spray behavior

- Digital & reproducible results: Comparability with reference test images for consistent process reliability

- Automatic test reports: Efficient documentation and archiving of all measured values

- Robust evaluation: thanks to intelligent algorithms in the DaVis software

- Collaborative working: Support from the powerful DaVis software, including free DaVis Viewer

- Flexible use: can be used inline, atline or online – depending on the production process

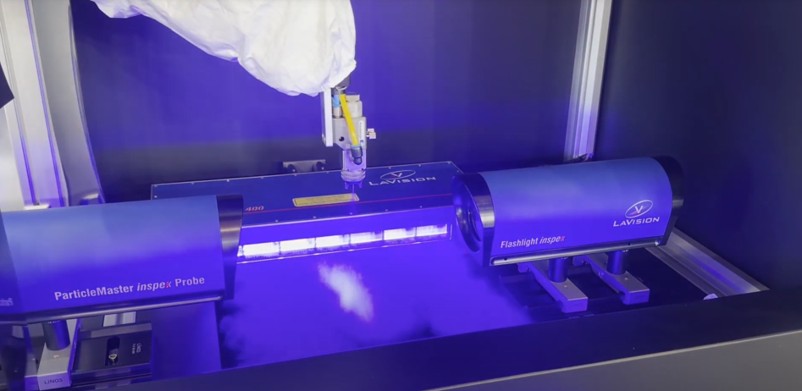

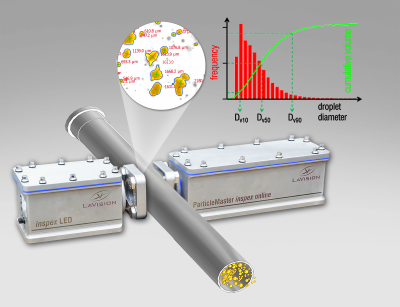

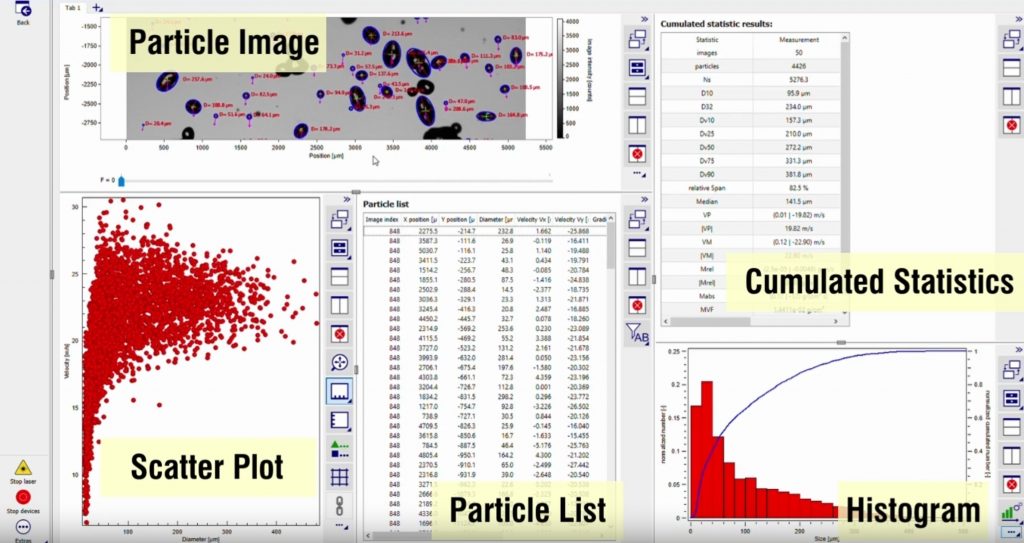

ParticleMaster inspex online

Reliable online droplet & particle size analysis

for production monitoring

LaVision’s ParticleMaster inspex online was specifically developed for particle and droplet characterization in industrial processes, e.g., for 24/7 online and inline production monitoring. Size parameters and particle statistics are communicated to the production environment continuously or on demand. Common communication protocols enable easy integration into the production line.

- Droplet size & distribution: Detailed analysis of particle density & droplet sizes

- Particle homogeneity: Optimization of uniformity & density for precise coating layers

- Dynamic image analysis (DIA): Highest precision for particle measurements

- Flexibly expandable system: Adaptable to different liquids & application methods

- Digital data evaluation: Automated analysis & real-time visualization

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

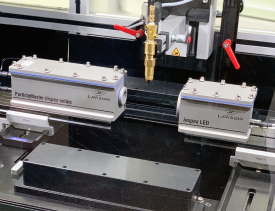

System & components

- Online probe with integrated dynamic image analysis system

- Online LED lighting unit

Measured variables & analysis areas

- Particle concentration: Number and mass concentration within the spray jet

- Particle homogeneity: shape, density and uniformity across the spray cross-section

- Particle size distribution spectrum: detection of minimum to maximum diameters (e.g. 4 µm – 1,000 µm) depending on the application

- Spray density profiles: Distribution of particle concentration over the width and depth of the spray

- Particle velocity (optional for combined measurement): Velocity and dynamic distribution of individual particle dropletsThese measured variables enable precise quality control and process optimization.

Features and equipment

- Common communication protocols enable simple integration into the production line.

- Machine monitoring via common communication protocols (e.g. Modbus)

- Online in-situ particle imaging

- No sample preparation required

- Simple integration on process sight glasses

- Robust sensor design (IP67)

- Fully calibrated ex works

- Automated 24/7 operation

- The ParticleMaster inspex online is factory calibrated and IP67 protected for use in harsh environments.

Advantages for production monitoring

- Continuous data acquisition: Permanent feedback on the quality of the spray job

- Digital & comparable results: Repeatable measurement data for reliable quality assurance

- Automated data acquisition & evaluation: efficient integration into existing processes thanks to the powerful DaVis software

- Flexible use in the line: Suitable for inline, atline and online test stations within the production chain

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationIntelligent quality control with the LaVision Quality Control Software - Seamless integration into production

Advantages of LaVision Quality Control Software for your quality management

- Automated measurement data processing:

Recording, analysis and comparison of all relevant spraying parameters in a central platform - Online monitoring and control:

Live data flows directly into the production control system for immediate process optimization - Standard-compliant quality assurance:

Documentation in accordance with international standards for easy traceability and auditing - Dynamic error analysis:

Automatic detection of deviations in spray pattern, spray cone and particle distribution - Increased efficiency through automation:

Faster test cycles and higher test capacities thanks to digital processes - Long-term process optimization:

Continuous improvement of product quality and production stability

Online and inline production monitoring - maximum control in real time

- 24/7 online quality monitoring: seamless real-time monitoring of spray quality directly in the production line

- Automatic corrections: process deviations are detected directly and passed on to the control system

- Industry-compatible interfaces: Support of Modbus, TCP/IP and 24 V I/O for easy machine integration

- Integration into existing databases and QM systems: complete traceability and analysis in production control

Powerful features for maximum control

- Automated image acquisition & analysis: Fully automatic acquisition and calculation of spray pattern, spray cone and particle distribution

- User-defined operator and administrator interfaces: Individually customizable user interfaces for different user groups

- Recipe-based tests for quick product changes: Simplified test procedures for various spray products

- Comparison with reference samples & tolerances: Precise deviation analysis for standard-compliant quality assurance

- Central data management & export functions: Standardized data management for tabular results, spray images and test reports

- Machine control via standardized protocols: Seamless integration into automated production processes

LaVision Quality Control and remote software:

Online monitored optimum spray performance for your production line

Real-time data transmission: Continuous analysis of spray quality

Automatic process adjustment: automatic optimization

in the event of deviations

Industry-compatible interfaces Modbus,

TCP/IP, 24 V I/O

Seamless connection to existing

production systems

Central control & monitoring,

Remote access to multiple lines

Compatible with databases and QM systems:

Complete measurement data traceability

Intelligent warning function: Automatic notification of process deviations

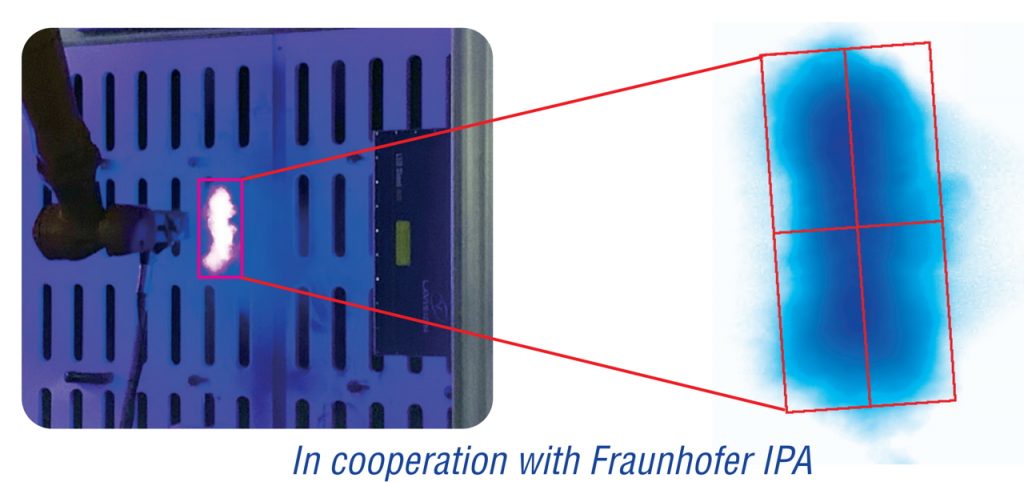

Customer reference example: Inline integration Krautzberger

Best performance for your production line too

We would be happy to advise you on how we can optimize online quality management

to the maximum in your production with innovative spray analysis.