More insight. More security. More efficiency. Optical diagnostics for ammonia combustion processes

Measurement expertise from LaVision

in combustion research

LaVision is a world leader in the optical diagnostics of combustion processes. Our high-precision measurement systems provide valuable insights into flame structure, temperature distribution, pollutant emissions and fuel mixture. State-of-the-art laser and high-speed camera technologies enable detailed analysis of combustion processes – both in research laboratories and in industrial applications.

The importance of detailed ammonia combustion analysis

As an alternative, carbon-free fuel, ammonia offers great potential for reducing CO₂ emissions in the energy and transportation sector. At the same time, its combustion requires precise control, as ammonia has a low flame speed and high NOx formation potential. To ensure efficient and safe use, all critical parameters must be precisely recorded:

Flame stability – preventing uncontrolled burns and flashbacks

Mixing behavior – Ensuring homogeneous fuel distribution for efficient combustion

Energy generation – Investigation of efficiency in ammonia combustion chambers of power plants

Industries & Applications

Shipping – Research into emission-free ammonia drives for large ship engines

Transportation and agriculture sector – development of high-performance ammonia combustion commercial vehicle engines

Industrial process heat – control of ammonia-based high-temperature processes

Advantages of combustion analysis by LaVision

- Precise real-time analysis: immediate evaluation of critical flame parameters.

- Highest spatial & temporal resolution: Detection of ultra-fast and smallest combustion processes.

- Multi-parameter measurements: Simultaneous analysis of temperature, flame stability, flow and emissions.

- Contactless measurement technology: No influence on the combustion process, maximum safety.

- NOx emission control: Direct identification of nitrogen oxides for optimized fuel control.

- Modular systems: Scalable for various applications, from basic research to industrial quality control.

Measuring method from LaVision for ammonia combustion

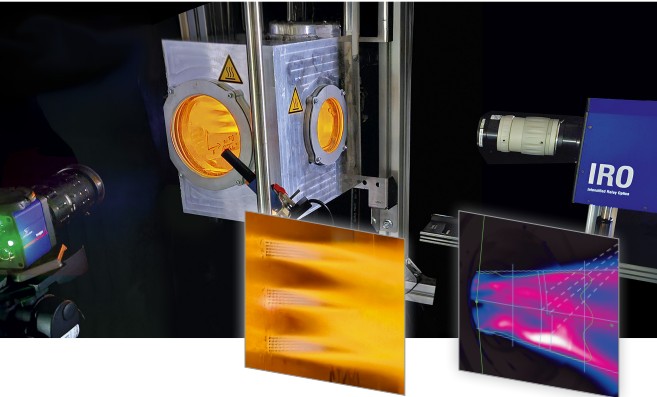

NOx camera solution for industrial requirements of detailed combustion analysis

With the NOx camera, LaVision is setting new standards for the combustion analysis of hydrogen and ammonia.

- Market-leading camera technology: direct visualization of nitrogen oxide (NOx) emissions in high-temperature flames

- Real-time monitoring of NOx generation: important findings for reducing harmful emissions

- Precise flame analysis: identification of high-temperature zones with critical emission values

- Ideal for industrial & scientific applications: NOx control in combustion chambers, hydrogen engines and power plants

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

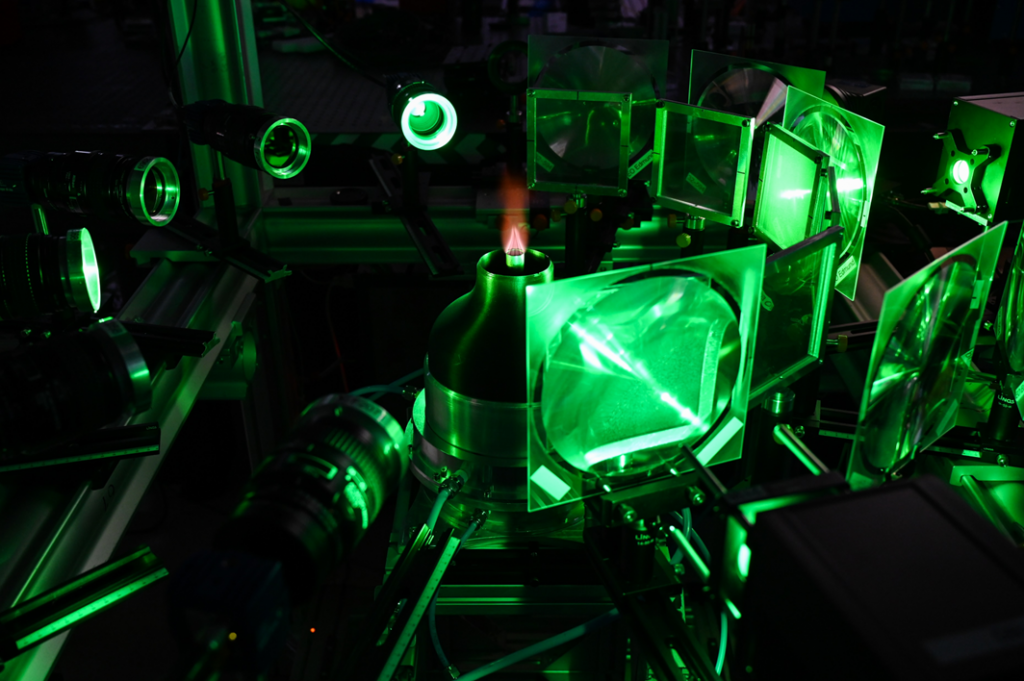

More InformationLIF (Laser-Induced Fluorescence)

- Detection of reactive species (e.g. OH radicals) for flame analysis

- Visualization of the fuel mixture in the combustion chamber

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationRayleigh Scattering

- Temperature measurement & investigation of mixing processes

- Optimized polarization measurement for more precise results

Tracer LIF

- High-frequency laser visualization of the ammonia mixture

- Real-time tracking of flows and fuel distribution

Questions & answers about ammonia combustion measurement

What needs to be considered with hydrogen combustion?

How does LaVision support research into ammonia combustion?

Our innovative measuring techniques provide high-precision data on temperature, flame stability and emissions – essential for the development of efficient, environmentally friendly combustion processes.

What are the advantages of Laser-Induced Fluorescence (LIF) for ammonia burns?

LIF enables contactless and non-invasive visualization of combustion processes with a high spatial and temporal resolution.

Why is the NOx camera particularly important for ammonia combustion?

The NOx camera analyzes the temporal and spatial combustion process in high resolution. It thus provides essential support in optimizing combustion systems in order to minimize pollutant emissions.

Can LaVision measurement technology also be used in basic industrial research?

Yes, our systems are modular and scalable – from basic research to industrial process optimization.

Request expert advice now!

The future belongs to sustainable fuels: With LaVision, you can rely on maximum precision, efficiency and safety for the optimum use of innovative energy sources.