See more. Analyze deeper. Optimize smarter. Optical measurement technologies

for industrial excellence

We make visible what counts for you:

Visualizing optical measurement technology with added value

You have to measure what is measurable,

and make measurable what is not yet measurable.

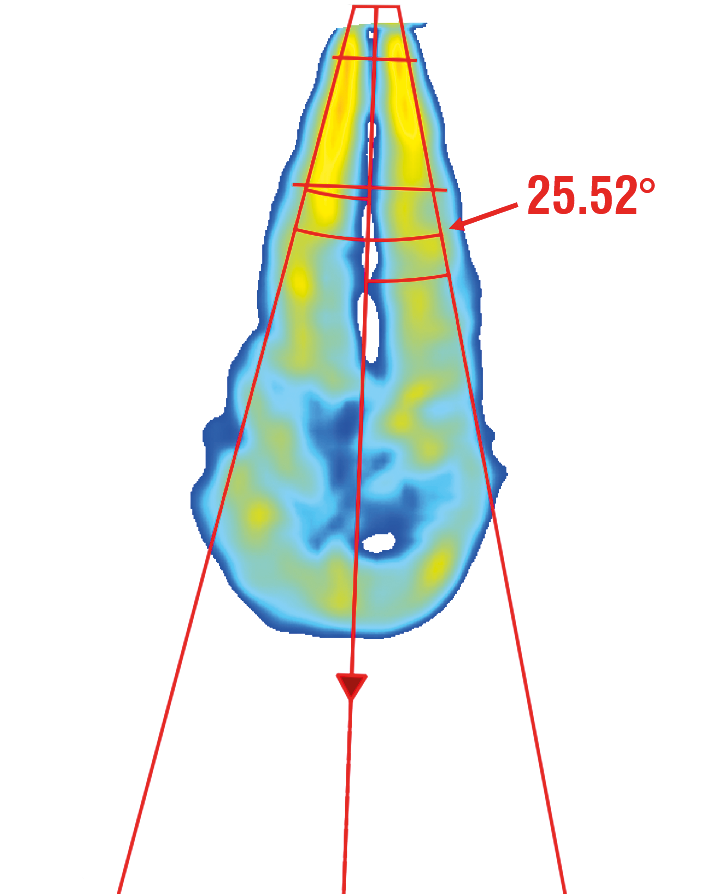

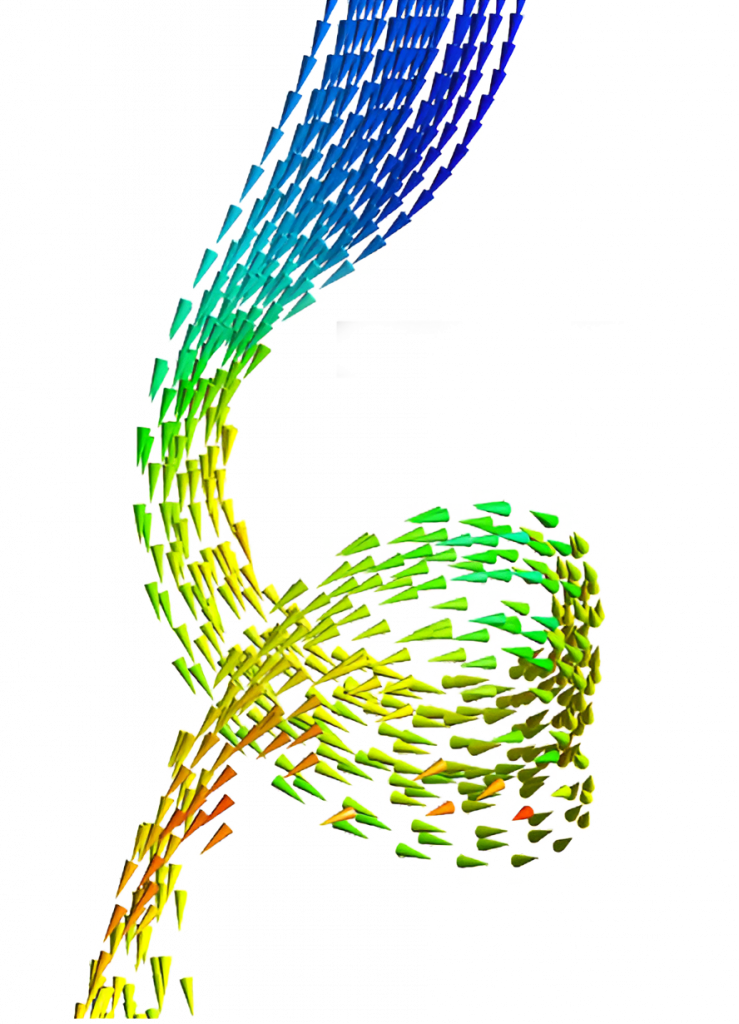

Spray analysis

Optical measurement solutions for precise visualizations

Optical measurement technology

for

vehicle development

Making vehicles more powerful

LaVision uses visualizing optical measurement methods to improve injection systems, aerodynamic properties and thermodynamic processes. In this way, we make a contribution to advanced vehicle development, reliable production monitoring and increasing the efficiency of ADAS systems in the context of autonomous driving. In addition, our visualizing measurement processes support future-oriented developments based on precise optical measurement technology.

Flow visualization

Making the invisible visible and analyzing it in detail

Services from LaVision

Spray analysis

Optical measurement solutions for precise visualizations

Optical measurement technology for vehicle development

Making vehicles more powerful

Flow visualization

Making the invisible visible and analyzing it in detail

Services from LaVision

More support for your company

LaVision offers you innovative optical measuring systems

with which you can carry out targeted flow, combustion, spray and particle analyses. Our imaging analysis methods record several process parameters simultaneously and thus enable precise visualizations. This gives you a real competitive edge in research and industry.

Our comprehensive customer service supports you in every project phase

from the initial consultation and installation through to monitoring practical measurements and data evaluation. Our experts have in-depth practical knowledge of a wide range of applications and are on hand to help you implement your projects – efficiently and purposefully.

Close cooperation and collaboration with leading companies

We work closely with partners from the automotive, aviation, chemical, pharmaceutical and cosmetics industries as well as with renowned research institutes to ensure that our solutions meet the highest technological standards. This is how we strengthen your competitiveness in the long term.